Efficient Customer Service and Security

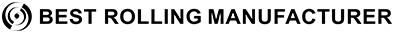

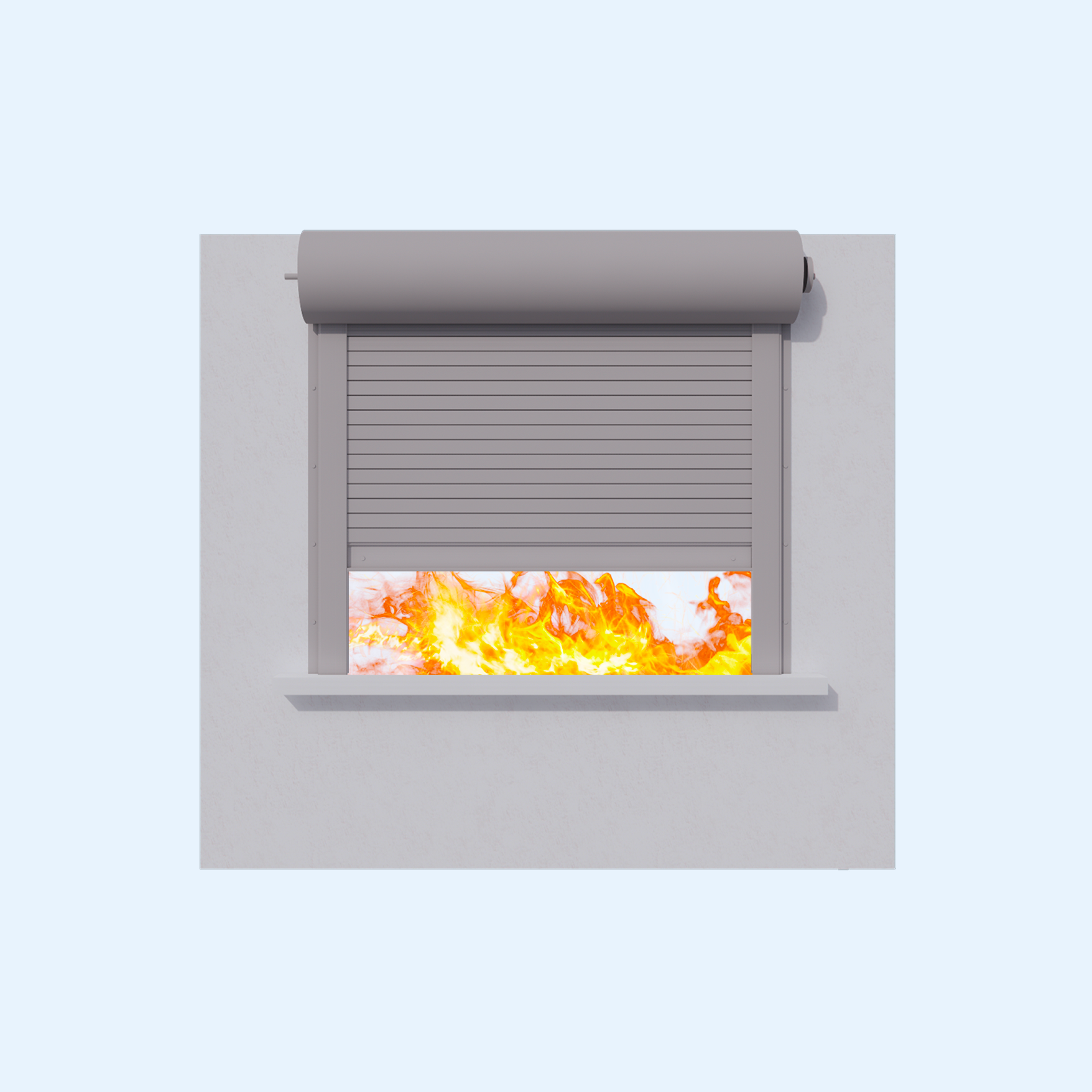

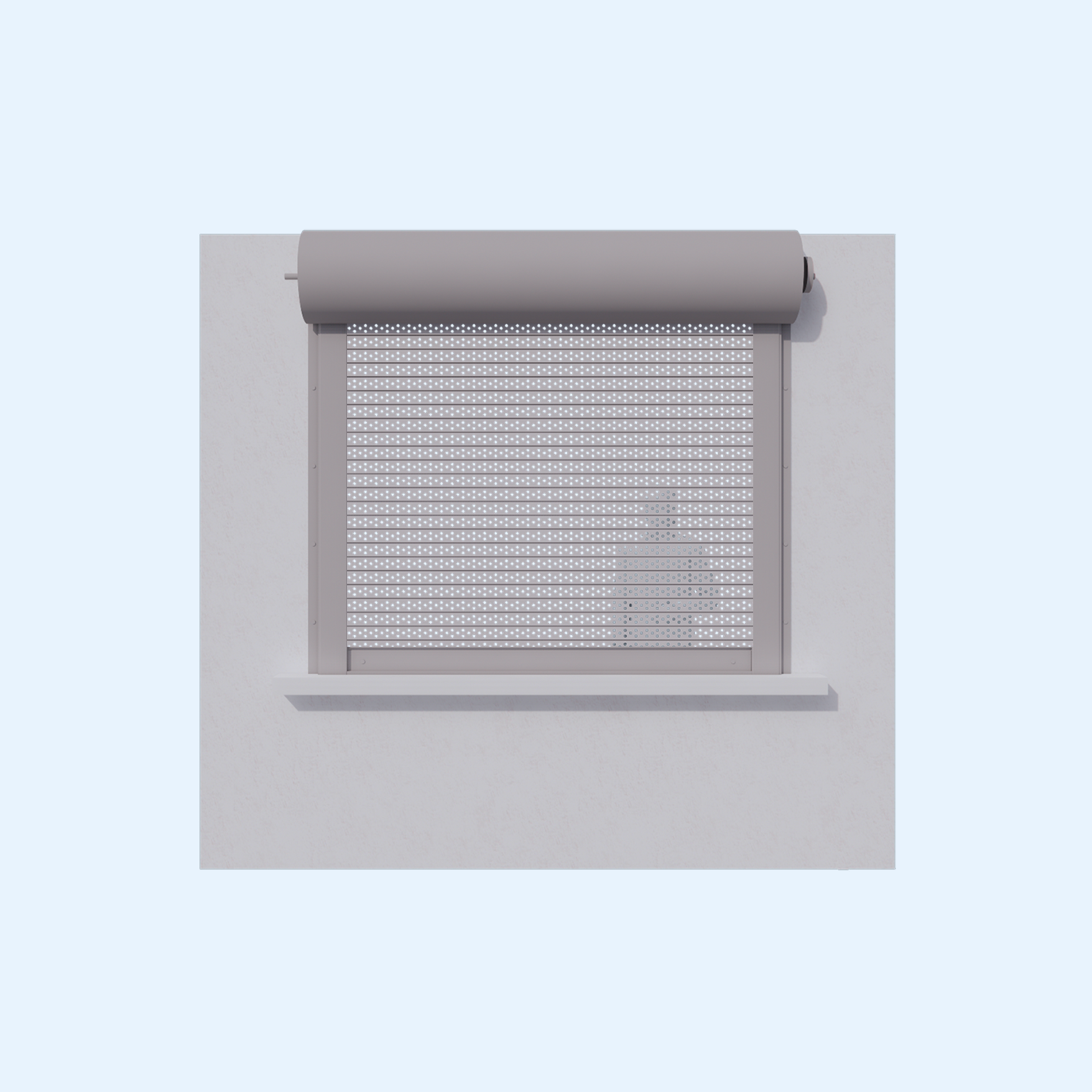

Counter rolling doors excel in optimizing customer service efficiency while ensuring security. Designed to securely close during non-operational hours, these doors safeguard the counter area’s contents. When open, they provide a seamless point of interaction between staff and customers, with quick and easy operation facilitating efficient service transactions. This dual functionality, seamlessly blending security and operational ease, positions counter rolling doors as invaluable assets for businesses seeking to enhance both customer service and overall security.