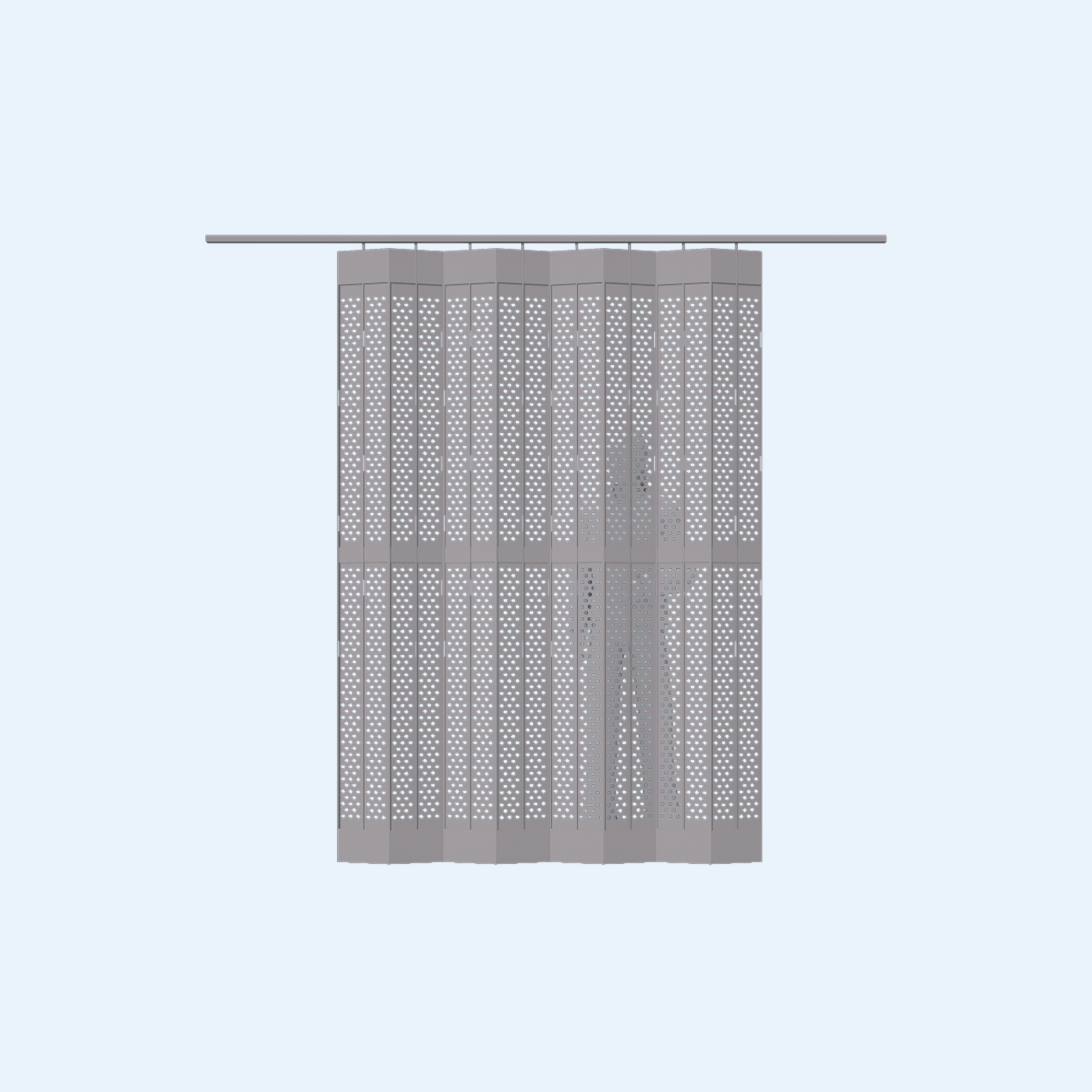

Side Folding Perforated

Overview:

Side Folding Gates are an excellent means of security and crowd control, allowing visibility for applications that may not be conducive for Coiling Grilles & Doors. Side Folding Gates can accommodate a multitude of special applications such as sweeping radius curved storefronts, corner locations and limited headroom conditions.

Perforated panels with 3/16” (5mm) diameter holes providing a 51% visibility and ventilation through the panels.

Colors:

- Complete visibility without the risk of reaching beyond the storefront

- Available in various colors and finishes

- Options include locks, pass-through doors, and additional accessories

- Emergency egress options: Bi-part egress door or Full egress door (36” x 80”) as per local building code requirements; panels perforated for egress door

- Complies with city visibility code requirements; not eligible for wind, fire, smoke, and/or sound ratings due to curtain openings

LISTINGS

Meets city visibility code requirement. Due to the perforated curtain this door not qualify for wind, fire, smoke and/or sound rating.

SIZE

Standard construction in a range of sizes up to 30′ wide x 30’ high.

Please contact us if your opening is larger—sizes available of 60′ wide or more upon consultation.

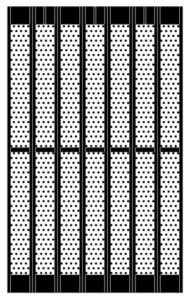

CURTAIN

The top and bottom of each section is fitted with an aluminum panel 4” (102mm) high. This panel consists of an aluminum extrusion 1/16” (1,6mm) thick and composed of modules with a 15° angle between them to facilitate the operation of the closure.

Perforated Panels – The top and bottom of each section is fitted with an aluminum panel 4” high (102mm). This panel consists of an aluminum extrusion 1/16” (1,6mm) thick and composed of modules with a 15° angle between them to facilitate the operation of the closure. The curtain is constructed of 6” (152mm) wide modules linked together by a continuous aluminum hinge. These hinges hold steel perforated panels with 3/16” (5mm) diameter holes providing a 51% visibility and ventilation through the panels.

MATERIAL & FINISH

Curtains have typical exterior finish in Mill Finish, White, Black and Bronze.

Additional options include: Copper, Galvanized, Stainless Steel, Galvalume, Prime Painted Galvanized & Powder Coated. Exterior skin is available in 1/16″ thickness.

WARRANTY

1-year warranty against defects in materials and workmanship

OPERATION

Manually operated – Easily slides into wall pocket

WEIGHT

Perforated Panels – Weight Per Surface Of Closure

1,90 lb/sqft = 9,3 kg/m2

Load requirements are greater when the closure is in the stacked position.

The support structure must be able to carry the weight of a fully stacked closure.

Stacked Linear Weight = Weight per surface of clousure X Height of closure X 8

Load requirements are greater when the closure is in the stacked position. The support structure must be able to carry the weight of a fully stacked closure. Stacked Linear Weight = Weight per surface of clousure X Height of closure X 8

TRACK

A. Curtain shall be hung from an overhead track 1-5/16” (33mm) wide by 1-9/16” (40mm) high. Track shall be tempered aluminum alloy 6351-T6.

B. Curves where required shall be 14” (356mm) radius standard.

STACKING

Stacking shall not exceed a depth of 1.15” per foot of closure width plus 3” for each post (lead, end or intermediate). (95mm/lin. m + 76mm per post). Full egress doors add 7” (178mm).

4″ – 102mm min clearance both sides of track. If a pocket door is used, the door must not obstruct the entry dimension given.

POCKET REQUIREMENT

Interior pocket width, width 10″ – 254mm is recommended with a standard 14″ – 356mm radius and B at 12″ – 305mm

LOCKING

A. Lead post shall be equipped with a hook bolt lock with Best cylinders each side.

B. Lead post shall engage a full height wall jamb.

C. Trailing post shall be self-locking at the top and bottom inside the storage pocket.

D. Free floating intermediate posts shall be located at all curves and at recommended intervals of 10 feet (3m) or 5 feet (1,5m) for counter top units. Intermediate posts shall be equipped with self- adjusting spring loaded drop bolts activated from the inside only. Drop bolts shall engage dustproof stainless steel receptacles.

CURTAIN PATTERN

Best S-126 — Openstyle brick pattern. The curtain is constructed of vertical rods of 5/16” (8mm) in diameter. The spacing between the rods is 2-5/8” (67mm) in a brick pattern. These rods are linked together by flat horizontal bars of 1/8” x 5/8” x 6-5/8” (3mm x 16mm x 168mm). These bars are spaced vertically every 12” (305mm) by aluminum sleeves of 1/2“ (13mm) in diameter.

Best S-12 — Openstyle long brick pattern constructed of a combination of rods and solid modules. The curtain is made of vertical rods of 5/16” (8mm). Each rod is contained in an aluminum tube that measures 1/2” (13mm) in diameter. Spaced every 3“ (76mm), these rods are linked by two series of horizontal modules of 2” (51mm) high. These module series are spaced vertically every 12” (305mm).

Best S-525 — Openstyle short brick pattern constructed of a combination of rods and solid modules. The curtain is constructed of vertical rods of 5/16” (8mm) diameter spaced out at every 3“ (76mm). These rods are linked together by 2” (51mm) modules spaced vertically every 14” (356mm), by aluminum sleeves of 1/2” (13mm) in diameter.

Best Solid — Opaque Style vertical solid slats. The curtain is constructed of 6” (152mm) wide modules linked together by a continuous aluminum hinge. These hinges hold aluminum panels 5-3/8” (136mm) wide and 1/16” (1,6mm) thick completely recessed throughout their full height.

Best 1212 — Solid style long brick pattern constructed of a combination of rods and solid modules. The curtain is constructed of modules 1/16” (1,6mm) thick arranged in a checkerboard design of 3” (76mm) c/c. These modules are linked together by hidden aluminum and steel rods of 5/16” (8mm) diameter. The height of the panels will be 12” (305mm).

Best 99 — Solid style short brick pattern constructed of a combination of rods and solid modules. The curtain is constructed of modules 1/16” (1,6mm) thick arranged in a checkerboard design of 3” (76mm) c/c. These modules are linked together by hidden aluminum and steel rods of 5/16” (8mm) diameter. The height of the panels will be 9” (229mm).

LOCKING

Top and bottom locking posts with key cylinders one or both sides are available for either end of the curtain.

Large sections may be divided by incorporating bi-part units as intermediate posts.

Second hook bolts on lead, end or biparts (recommended for closures over 12’ (3,7m) high or for more security).

High security or master keyed lock cylinders – customer supplied and factory fitted.

Solid aluminum block covering cylinder lock for additional protection (specify cylinder protection).

Architect to decide side of lock cylinders.

Additional intermediate post with shoot bolt to floor or counter.

TRACK

10” (254mm) radius curves (indicate location on plans).

Special radius curves (indicate location and radius on plans). Custom radius can be bent to match the design specified by client.

EGRESS COMPLIANCE

Bi-part egress door (bi-part post with interior thumb turn activation). Ideal choice.

Full egress door 36” x 80” (914mm x 2032mm) (where required by local building code). This egress door should be used only when the bi-part egress is refused (extra cost).