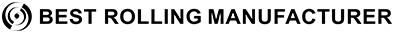

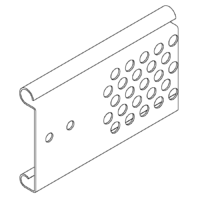

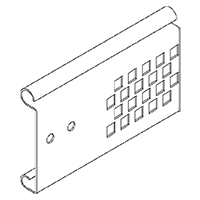

Perforated Rolling Door

Overview:

Hurricane and Other Approvals

Colors:

- The perforations in the door panels allow for airflow, promoting ventilation within the enclosed space

- Visibility through the door is maintained, enabling natural light to enter the premises even when the door is closed

- The design of the perforations can be customized to meet specific aesthetic and functional requirements

- Perforated rolling doors are built to withstand the rigors of industrial use, ensuring long-term durability and minimal maintenance requirements

- Titan Locking System with lock rods over ½” thick built to withstand potential security breaches and operator misuse

- Operation options by motor, chain, hand-crank, or manual push up depending on the weight and frequency of operation

- Perforated slats available in 2.0″ or 1.5″ slat widths

LISTINGS

This door meets city visibility code requirements.

Hurricane Approved as per the Florida Building Code for wind pressures of:

- +70/-70 mph

Due to the perforated curtain this door does not qualify for fire, smoke and/or sound rating.

SIZE

Standard construction in a range of sizes up to 30′ wide x 30’ high.

Please contact us if your opening is larger—sizes available of 60′ wide or more upon consultation.

CURTAIN

Perforations available in Square or Round pattern design. Slats available in 2.0″ or 1.5″ slat widths.

Pattern is available in Regular (for 2.0” slats) or Micro-Perforations (for 1.5” slats). Both perforations sizes conform to city visibility requirements.

MATERIAL & FINISH

Typical exterior finish in Galvanized, White, or Grey. Additional finish options include: Stainless Steel, Galvalume, Aluminum Mill, and Powder-Coated.

Curtain is available in 24, 22, 20 and 18 gauge. For a perforated door, the gauge is typically determined by door size.

WARRANTY

1-year warranty against defects in materials and workmanship

OPERATION

Motor, Chain, Hand-Crank or Push-Up operation available based on size, weight or frequency of operation.

Battery backup available to ensure operation in the event of power failure or blackout.

USAGE

Standard construction is up to 15,000 cycles per year with High Cycle Construction available for doors expected to be operated more than 15,000 cycles per year, i.e. parking garages, sally ports.

BOTTOM BAR

Bottom Bar options include: Single Angle, Double Angle, Tubular (extruded alum.) or “T” bottom bar.

Bottom Bars are typical Galvanized steel finish.

Additional options: Clear Anodized, Brass, Copper, Mill, Stainless Steel, Hot Rolled Steel, Powder Coated, Paint.

LOCKING

Chain Operation:

- Wall mounted chain keeper

- Zinc plated steel slide bolt with padlock provisions

Push-Up or Hand-Crank Operation:

- Slide Locks

- Round Locks

- Cylinder Locks for locking at bottom bar

Motor Operator:

- No additional locking required as the motor has automatic features to prevent the door from being lifted.

- Additional locking mechanisms include Slide Locks, Round Locks or Cylinder Locks for locking at bottom bar

*bottom bar design effects locking option available

GUIDE MATERIAL

Guides are typical Galvanized steel finish.

Additional options: Clear Anodized, Brass, Copper, Mill, Stainless Steel, Hot Rolled Steel, Powder Coated, Paint, Strip Seal, Single Angle, Double Angle, Tubular, Slope Bar, Slide Locks.

COUNTERBALANCE ASSMEBLY

Counterbalance Assembly can be Hot Rolled A36, Galvanized, Stainless Steel, Aluminum, Torsion Spring, Cycle 17.5 to 400M, Welded Tabs, Tapped Holes, Redi-Tube Motor, Thru-Shaft Push-up, Inside Charge, Lock Shaft Collar, Keyed, Bolted.

BRACKET PLATES

Bracket Plates can be Brass, Copper, Hot Rolled A36, Stainless Steel, Aluminum, Galvanized, Powder Coated, Stop Lock Bearing,Internal Charge, Chain Gearing, Round Bracket, Square Bracket, Single Gear Reducer.

HOOD / COVER

Hoods are typically furnished if the coil is exposed. If provided, hoods are typical Steel Galvanized Finish.

Additional Finish Options: Brass, Copper, Stainless Steel, Galvalume, Prime Painted, Powder Coated

Standard shape is a round cover. Options for squares or hexagonal upon request.

For aesthetic purposes if the coil is exposed there is a fascia option to hide the door in up position. Motor cover available for preventing weather intrusions and security protection.

For hand operation different cover options are available for chain mechanism to accommodate weather intrusion, security protection and aesthetics.

Covers can be provided for all exposed mechanical parts, consult the factory.

PARTIAL PERFORATED

Combine perforated slat section at eye-level with solid slats in the same curtain. Allows for ventilation with added security, while still being able to see into the next space.

PASS DOOR

Hollow metal doors are ideal in applications where space is too limited for the installation of a standard entry door. A pass door conserves energy by allowing building access via a smaller opening versus opening the entire door.

FAST ACTING DOORS

For high traffic openings or where air flow or temperature control is critical, doors can be designed to operate at more than twice the speed of typical doors, or up to 2 ft/sec

HIGH CYCLE SPRINGS

High Cycle performance available up to 100,000 cycles at an additional cost (i.e. parking garages, sally ports).

SLOPING FLOOR

Bottom bar design can be sloped to accommodate floor conditions that are not level. This allows for the opening to be entire secure and touch the floor at all points.

SAFETY EDGE

Addition of a safety edge to the bottom bar prevents damage to an object in the door’s pathway in addition to minimizing damage to the closure itself. If trying to close the door, the door will stop and open again.